The lintel above a window serves a vital purpose, just like the one above a door. Lintels are primarily used in masonry and brick buildings to support the weight of structures above windows, doors and other wall openings. They are available in different materials, and their installation is guided by the relevant building codes.

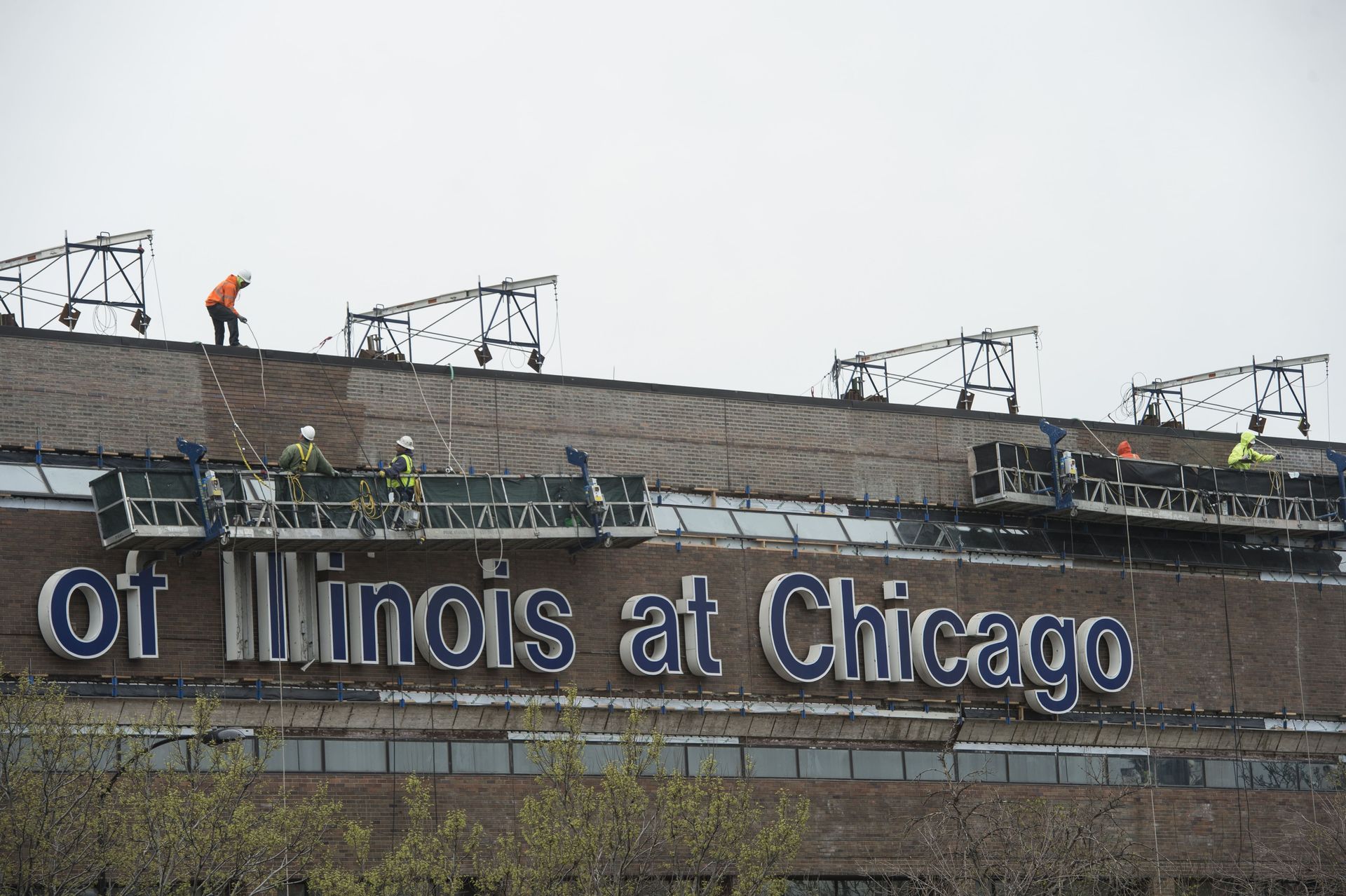

RestoreWorks has repaired and replaced lintels in various types of buildings, including commercial buildings, churches, schools, and museums. We share how to identify potential lintel failure, the different types of lintels, and why you need to hire a professional company such as RestoreWorks to do lintel repairs.

How to Identify Underlying Window Lintel Failure

Lintels are placed horizontally across the top of a wall opening, extending past either end. The lintel material depends on the structure’s support needs and the building’s aesthetic requirements. They are an important structural element. How do you identify window lintel failure? Look for the following:

- Cracks in the window glass indicate that the window is carrying structural weight rather than the lintel.

- Cracked or missing mortar around the upper corners of the window.

- Depressions along the window structure.

Is the lintel above the window made from steel? It might be pitted, and rust is wearing down the metal, causing the lintel to fail. A crack in a stone lintel is also an indication of failure, and it should be replaced immediately. Not doing so is a safety risk.

Types of Lintel Reinforcement Used in Construction

In some buildings, lintels provide structural support and serve a decorative purpose, just like the stone lintels above the second-floor windows of Chicago’s historic Yondorf Block and Hall. What types of lintel reinforcement materials are used in construction?

Brick. Often used in masonry construction, brick lintels are created by placing several layers of bricks over the opening to distribute the load.

Reinforced Brick. A mild steel bar is placed lengthwise in the space between adjacent bricks to reinforce the lintel.

Timber. Generally used in residential and traditional construction, timber lintels can be costly and are vulnerable to fire.

Reinforced concrete. Suitable for all loads and spans, reinforced concrete lintels are strong, rigid, economical and fire-resistant.

Steel. Steel lintels are ideal when openings are large and the superimposed loads are heavy.

Stone. They have span limitations, and the stone lintel’s thickness is its most important design factor.

The Potential Dangers of a Cracked Window Lintel

Why is a cracked window lintel dangerous? Lintels carry the extensive weight of the bricks or stones above, and when the lintel starts to fail, the materials begin sagging downwards. Ultimately, the pressure is so extensive that the lintel breaks or the wall collapses, causing damage. In a glass window, the pressure could make the glass crack and ultimately break, severely hurting people walking beside the building or staff seated next to the window.

Hire Professionals for Concrete Lintel Repair

There can be no quality or safety compromise with lintel repair and replacement. Hire professionals to perform the repair or replacement, and you are guaranteed the work is of the highest standard. RestoreWorks is your best choice. Our process includes performing a thorough inspection to identify the cause and extent of the damage and what is needed to restore structural integrity.

When we find heavily rusted steel lintels, experience shows it is better to replace the lintel. Today’s building materials are superior to those used decades ago and provide longer-lasting results. RestoreWorks adds flashing, end dams, and weep systems during the lintel repair process. When RestoreWorks replaces lintels, it restores structural integrity, improves water tightness, and adds decades to a building’s life.

RestoreWorks is a professional service provider with decades of experience. We provide lintel and shelf flashing repair services to clients throughout the Chicago metropolitan area and Northwest Indiana. Has a building inspection highlighted there might be problems with several windows? Did you request the inspection because you saw slight cracks next to the lintel above a window? Contact RestoreWorks today.